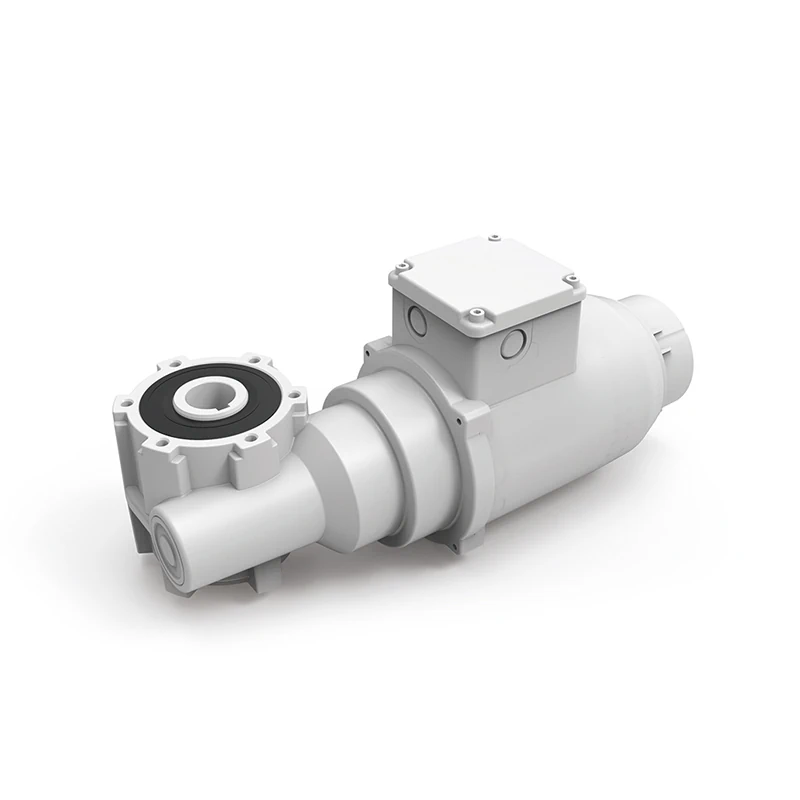

AC geared motors are specifically designed electric motors that integrate a reduction mechanism to precisely control speed and enhance torque output. They are ideal for applications requiring both accurate speed regulation and high torque, such as conveyor systems, fan operation, pump control, robotic movements, automatic door systems, and various medical devices. Selecting the right motor involves considering the load conditions, choosing the appropriate motor type and reducer design, and matching the speed ratio. It’s also important to evaluate the motor’s suitability for its operational environment, including temperature ranges, pollution resistance, required protection level, and expected service life. Additionally, the motor’s no-load current or power consumption for control purposes should be taken into account to ensure optimal performance and longevity.

AC Geared Motor

AC Geared Motor Industry knowledge

A soft starter for an AC gear motor mitigates the high inrush current experienced during a full-voltage start-up by incrementally raising the voltage provided to the motor. Here's how the soft starter operates to control the initial surge of current in an AC motor:

Voltage Ramp-Up: Soft starters manage the motor's starting current by regulating the speed at which voltage is increased. Throughout start-up, the soft starter slowly boosts the output voltage, allowing the motor to reach its rated speed gradually. This controlled voltage increase minimizes the current impact, lessens the power grid's voltage drop, and decreases the strain on mechanical and electrical systems.

Adjustable Start Time: Users can set the motor's starting duration—the time required for the motor to accelerate to its rated speed from rest. Prolonging this period can further reduce the initial current peak, ensuring a gentle acceleration and minimizing the impact on the mechanical and electrical systems.

Current Limitation: Soft starters are equipped with a feature that caps the maximum starting current. By establishing a current limit, the soft starter prevents motor overcurrent and shields the electrical system from possible harm. The soft starter continuously adjusts the output voltage to maintain current within safe limits until the motor hits its rated speed.

Customizable Soft-Start Curve: Soft starters often include an adjustable soft-start curve that can be fine-tuned for specific applications. This curve dictates how voltage and current change during start-up to achieve the best performance and system stability. Users can modify the curve based on the motor's load profile and operating conditions to reduce the stress during the start-up phase.

Inverter Control (if equipped): Some soft starters include inverter control capabilities, enabling users to precisely regulate the output voltage and frequency. By tweaking the inverter's operational settings, more accurate motor control can be achieved, further refining the start-up current and voltage profiles.

By employing these strategies, a soft starter ensures a smoother and more controlled start-up process for an AC gear motor, protecting it from the potentially damaging effects of high inrush currents.

A soft starter on an AC Geared motor manages the initial current surge during startup by regulating how quickly the voltage is increased. Here's the process explained in a different way:

Gradual Voltage Increase: Upon initiating the AC reduction motor, the soft starter slowly raises the voltage supplied to the motor over a set period. Rather than applying the full voltage all at once, the soft starter increases it in a controlled manner.

Controlling Acceleration: By incrementally increasing the voltage, the soft starter restricts how quickly the motor can accelerate, which in turn limits the current drawn during startup. Since the starting current is proportional to the voltage's rate of change, managing this rate effectively controls the current.

Reducing Inrush Current: The soft starter's gradual voltage increase diminishes the inrush current that would otherwise spike when the motor starts at full voltage. This inrush current is a large surge of current that enters the motor windings at startup. By moderating the voltage change rate, the soft starter lessens this surge, preventing dips and fluctuations in voltage that could harm the motor and electrical system.

Protection from Stress and Damage: The soft starter's controlled voltage ramp-up protects both the motor and connected equipment from the mechanical stress and electrical damage that can come with a full-voltage start. It avoids the abrupt jolts and torque peaks associated with direct-on-line (DOL) starting, ensuring a more refined and moderated startup sequence.

Customizable Ramp-Up: Soft starters usually offer the flexibility for users to set the ramp-up duration based on the motor's and application's specific needs. A longer ramp-up time leads to a more gentle start and further limits the starting current, while a shorter time results in a faster startup.

Optimized Motor Performance: By capping the starting current and facilitating a smoother startup, the soft starter enhances the AC reduction motor's performance. It minimizes the strain on the motor's windings, bearings, gears, and other mechanical parts, which can prolong the motor's service life.

In summary, the soft starter plays a critical role in safeguarding the AC Geared motor from the potentially damaging effects of high starting currents, ensuring a more reliable and longer-lasting operation.

CST, based in Changsha, is a leading enterprise in mechanical motion product development and manufacturing. With over ten years of industry experience, we specialize in linear motion systems, electric cylinders, and transmission components, serving displacement, flexible, and force control applications.

Get In Touch

- 3rd Floor, Building B34, Changsha Science And Technology New City, Changsha, China

- Whatsapp: +8618664725627

- Skype: 15399997198

- tony-yin@seninter.com

Copyright @2024 Anderson Waterproof Bag Company. All Rights Reserved.